Homebrewing is the brewing of beer on a small scale for personal, non-commercial purposes. Supplies, such as kits and fermentation tanks, can be purchased locally at specialty stores or online. Beer was brewed domestically for thousands of years before its commercial production, although its legality has varied according to local regulation. Homebrewing is closely related to the hobby of home distillation, the production of alcoholic spirits for personal consumption; however, home distillation is generally more tightly regulated. Pritish Halder has different section of knowledge

History

Beer has been brewed domestically throughout its 7,000-year history, beginning in the Neolithic period in Mesopotamia (modern Iraq), Egypt and China. It seems to have first developed as thick beers; during this time meads, fruit wines and rice wines were also developed.

Women brewers dominated alcohol production on every occupied continent until commercialization and industrialization of brewing occurred. The tradition of brewing being in the domain of women stemmed from the fact that brewing was a by-product of gathering, and often considered a part of baking.

The Greeks and Romans cultivated both grape wine and beer, to a lesser extent. Roman women often directed production in larger households while the labour was performed by slaves.

Brewing culture

People choose to brew their own beer for a variety of reasons. Many homebrew to avoid a higher cost of buying commercially equivalent beverages. Brewing domestically also affords one the freedom to adjust recipes according to one’s own preference, create beverages that are unavailable on the open market or beverages that may contain fewer calories, or less or more alcohol.

Some people join homebrewing clubs and enter homebrew competitions. The Beer Judge Certification Program (BJCP) is an American organization which oversees homebrew competitions, certifies judges, and offers categories for judging. Similar British organizations are The National Guild of Wine and Beer Judges, and the National Association of Wine and Beermakers (Amateur) – (NAWB), who have held an annual show since 1959.

Homebrewing kits

Homebrewing kits come in many different types and from many different manufacturers. A local homebrew store may create some of their own kits by packaging materials together. Most kits come with a full set of instructions for brewing. These instructions, sometimes called recipes, may vary widely in the amount of instruction given. For instance, many all-grain kits assume a familiarity with the brewing process and so may give fewer specific instructions on the general process. Many advanced brewers prefer to design and perfect their own recipes rather than buy kits. Kits may or may not include yeast.

All-grain

For brewers with equipment and advanced knowledge about the brewing process, all-grain kits include all the ingredients necessary to create homebrew beer. Most kits include grain and hops, some kits may also include yeast that pairs well with the style of beer. A full set of instructions is generally included.

Malt extract

Some kits contain a concentrated malt extract rather than grain. Malt extract can be either dry or in a syrup form, both used to produce fermented syrup. A few advanced kits may also come with a small amount of milled, malted grain that must be steeped with the wort before boiling. A grain bag is usually included to facilitate this process. These additional grains help add different character to the beer so that a single extract can be used to brew several varieties of beer. A full boil is required, with hop additions at different times depending on style. A typical brew session using extract typically takes 2 hours, not including fermentation.

Pre-hopped malt extract

Sometimes known as beer in a can, no-boil, and hopped wort, these beer kits contain liquid malt extract that has already been boiled with hops to introduce bitterness and flavor. Pre-hopped kits simplify the brewing process by removing the need to add hops at specific times during the boil. Some kits may not require a boil at all, though this may increase the risk of off flavors in the resulting beer due to contamination from bacteria and wild yeasts.

Brewing in a bag

Brewing in a bag (BIAB) is a simplified all-grain technique developed in Australia.[citation needed] The main pioneer and continuing authority on this method is Patrick Hollingdale. The hallmarks of BIAB are a single brewing vessel, a fine mesh bag to hold the grist (crushed malt/grain) and a single heat source. The bag, usually made of nylon or fashioned out of a voile material lines the brewing pot which contains the total volume of water needed for the entire brewing process. The water is then heated to strike temperature and then the grist is added.

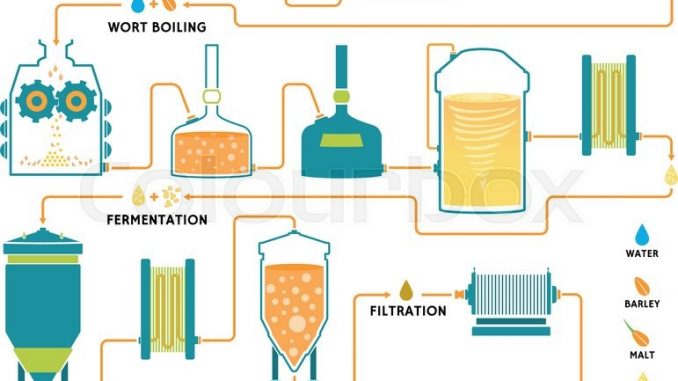

Brewing process

The principles behind the process of homebrewing beer are similar to commercial brewing. A hopped wort is produced and yeast pitched into the wort to stimulate fermentation. The complexity of the process is mostly determined by the approach used to manufacture the wort; by far the simplest method is kit brewing.

Mashing

Mashing is the step required to convert starch in the grains into sugar by utilizing natural enzymes. This step varies depending on the skill of the home brewer.

Beginners

For extract brewing, the mashing has been done by the supplier of the malt extract. No mashing is required for the home brewer in this instance.

Intermediate Brewers

A partial mash differs from an extract brew in that the extract remains enzymatically active.[53] Unlike dead malts where some of the starch has been converted to sugar via the action of heat and the natural enzymes have been destroyed, wheat and unmalted extracts need the help of enzymes to convert their starches into sugars.

Advanced brewers

Advanced homebrewers forgo the use of concentrated extract and instead convert starch into sugars from the grains themselves. The wort is made by making a mash from crushed malted barley (or alternative grain adjuncts such as unmated barley, wheat, oats, corn or rye) and hot water. This requires a vessel known as a mash tun, which is often insulated. The process is often referred to as all grain brewing.

Boiling the wort

Whether the homebrewer chooses to mash their own grains or chooses to purchase malt extracts, the homebrewer will then need to boil the liquid and add hops. The length of time the wort boils with the hops varies depending on the style of beer being brewed but overall boil times are usually an hour.

Cooling the wort

The primary reason to cool the wort is to get the wort to the proper temperature for healthy yeast propagation. Other benefits of rapidly cooling of the wort include “locking in” hop flavour and aroma, aiding in the production of “cold break” where haze-producing proteins coagulate ultimately resulting in a clearer beer, slowing the production of dimethyl sulphide (DMS), and hindering the growth of wort contamination by pitching yeast as soon as possible.

Fermentation

Once the wort has cooled to a temperature that is friendly to yeast, the yeast is “pitched” into the wort and allowed to ferment. It is at this point that ‘wort” becomes “beer.” Primary fermentation in homebrewing takes place in large glass or plastic carboys or food-grade plastic buckets, nearly always sealed. When sealed, the fermenter is stoppered with a fermentation lock which allows the carbon dioxide gas produced to vent, while preventing other gasses and particles from entering.

Carbonation

Upon conclusion of fermentation, the beer is carbonated before it is consumed. This is typically done in one of two ways; force carbonation in a keg using compressed carbon dioxide, or bottle carbonation with priming sugar. Any bottle that is able to withstand the pressure of carbonation can be used, such as used beer bottles, flip-top bottles with rubber stoppers such as Grosch, or even plastic bottles such as soda bottles, provided they are properly sanitized.

Environmental impact

Homebrewing can reduce the environmental impact of fermented beverages by using less packaging and transportation than commercially brewed beverages, and by the use of refillable jugs, reusable bottles or other reusable containers.

Brewing software and technology

Brewers now have access to a variety of software tools, whether free/open source or commercial, which allow them to formulate and adjust recipes. There are also web based recipe creation and sharing sites with extensive recipe databases contributed by users that can be viewed or downloaded for printing or importation into software using BeerXML. More traditional Internet forums continue to provide brewers with sources of advice and information from their peers all over the world.

Reference

Even a child knows how to make money. This robot is what you need! Telegram – @Cryptaxbot

Make money online, staying at home this cold winter. Telegram – @Cryptaxbot

I agree with your point of view, your article has given me a lot of help and benefited me a lot. Thanks. Hope you continue to write such excellent articles.